We are open and transparent of the fact that our sensor will not support every bike make/model off the shelf. It can be modified to support any bike if you want to make your own parts. While we know some will not be able to go this route, we hope that folks who have the skills to do this will share their work. If you share your parts with us we will post your project on our website for others to use. Parts can be printed at places such as proto labs. We have had good luck with their quality and delivery times. Use these parameters when printing your STEP files:

- PA 12 Black

- Normal Res

- Standard

- Multi Jet Fusion

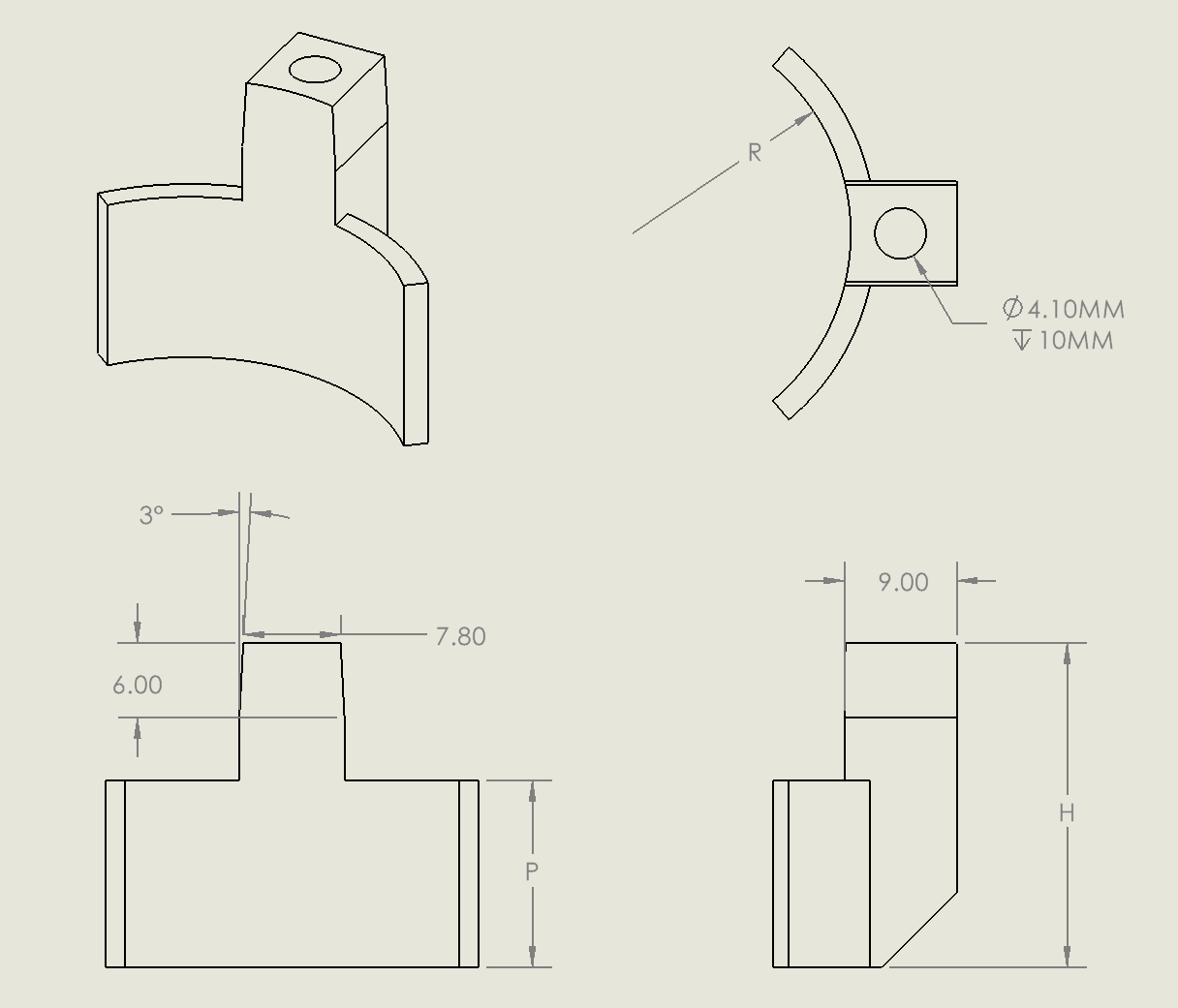

As an example, we have provided a modification of our rear sensor to support a Canyon Spectral. The Canyon Spectral has embedded it’s bearings into the frame. The main pivot bolts are fixed with the link and therefore cannot be measured with our stock paddle design. We designed a new paddle that extends and mounts on the frame. When the main pivot rotates, the relative angle of the pivot moving can be measured.

The following parts will need to be ordered at McMaster. The threaded insert is pushed into your paddle with a soldering iron. Just heat up your soldering iron and place the insert onto the tip of the iron. Once the insert is up to temperature, you can simply push it into the plastic. Do this in a well ventilated area since the fumes from the melting plastic are probably not the best to breathe in.